How to extend / shorten switchblock wiring

Posted: Mon Feb 21, 2022 4:12 pm

I was looking at an old post of mine from another forum and thought it might be useful on here. Hoping you all can see the PhotoBucket images - I don't have them on my computer anymore and to be honest I'm kinda surprised I can still see them:

This method can be used for lengthening or shortening the wiring going to your switchblocks. For ease of posting, I’ve chosen to shorten this one. If you are lengthening yours (like for a streetfighter bar conversion), then you pretty much do the same thing except adding a piece of wire in the middle (duh) and having 2 solder joins per wire instead of one. You can either add some extra outer sheathing, buy a new length, or use heatshrink.

We are going to re-use the pins and the connector block in this exercise. You could go all full retard and buy something like fancy Deutsch connectors and think you’re improving things but if you actually look inside your switchblock and see how the switches work, well, fancy connectors in this application would be like putting racing slicks on a warehouse hand trolley. Also, changing the connectors means if you ever have to buy another switchblock (like if you slide down the road and FUBAR this one) you have eliminated the plug and play aspect and are in for another night with the soldering iron / crimpers.

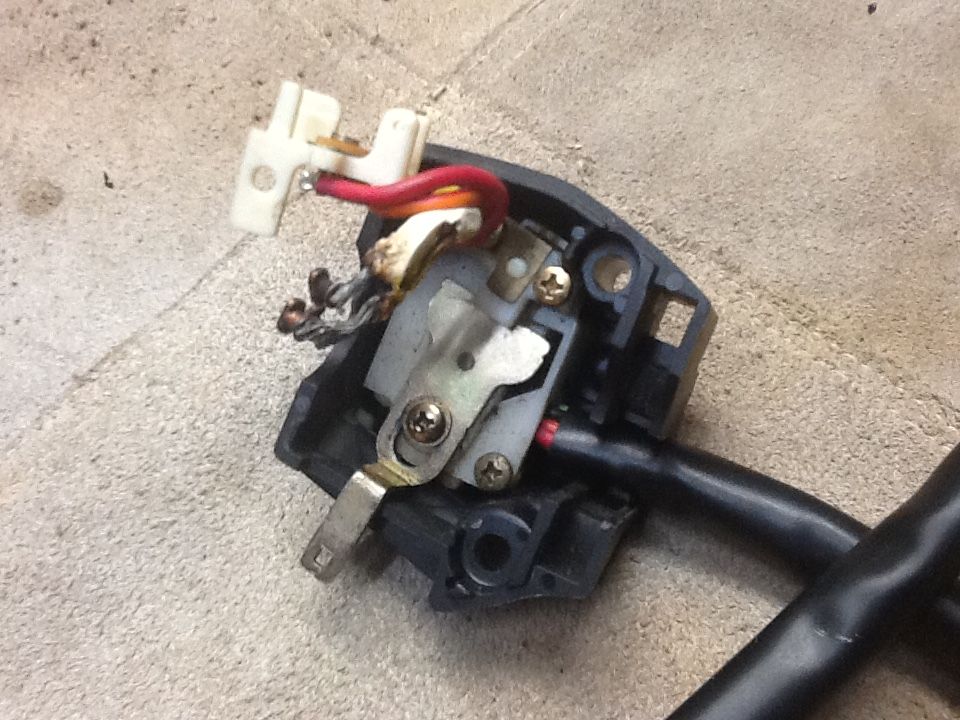

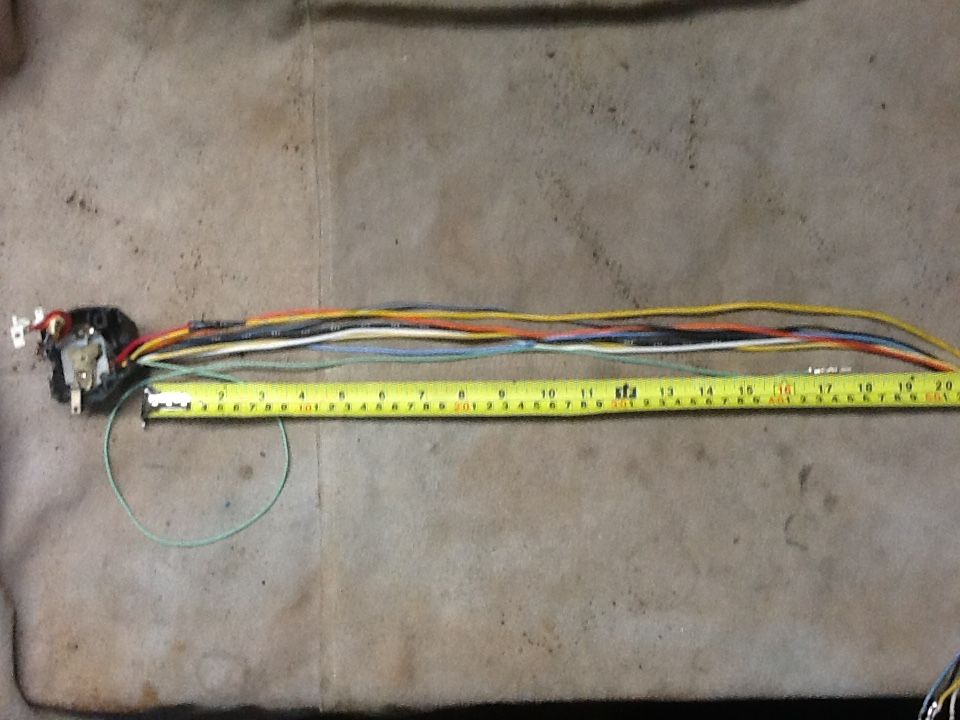

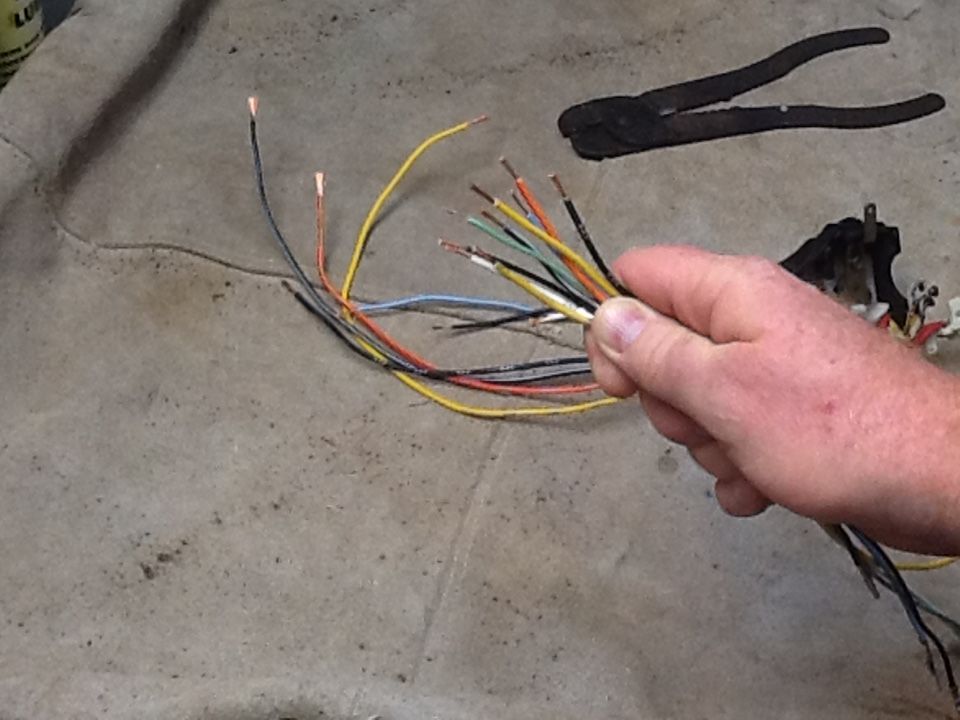

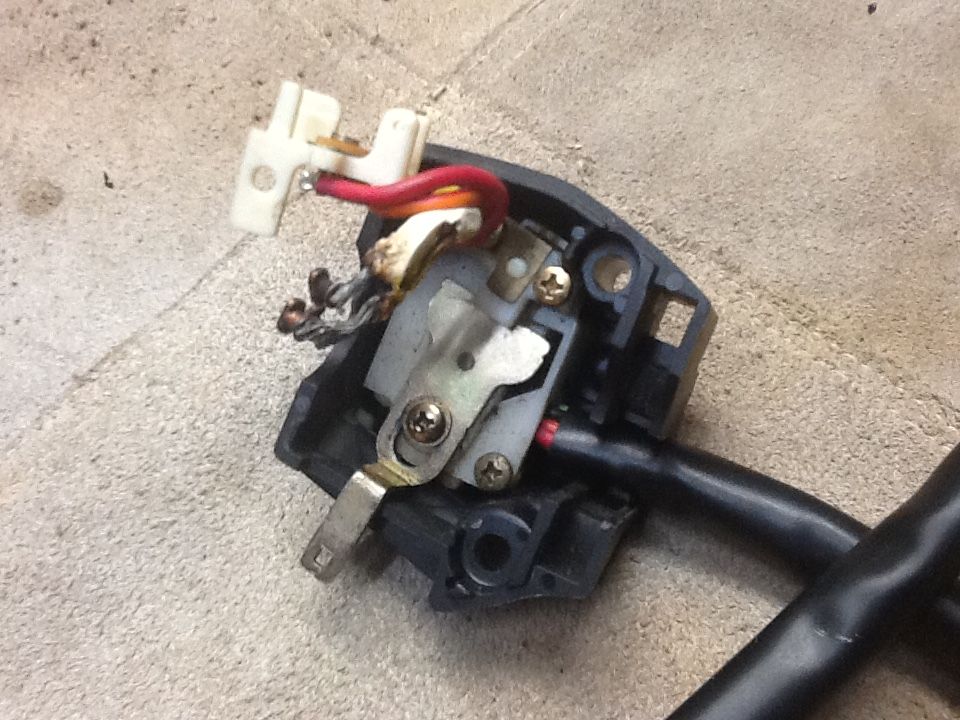

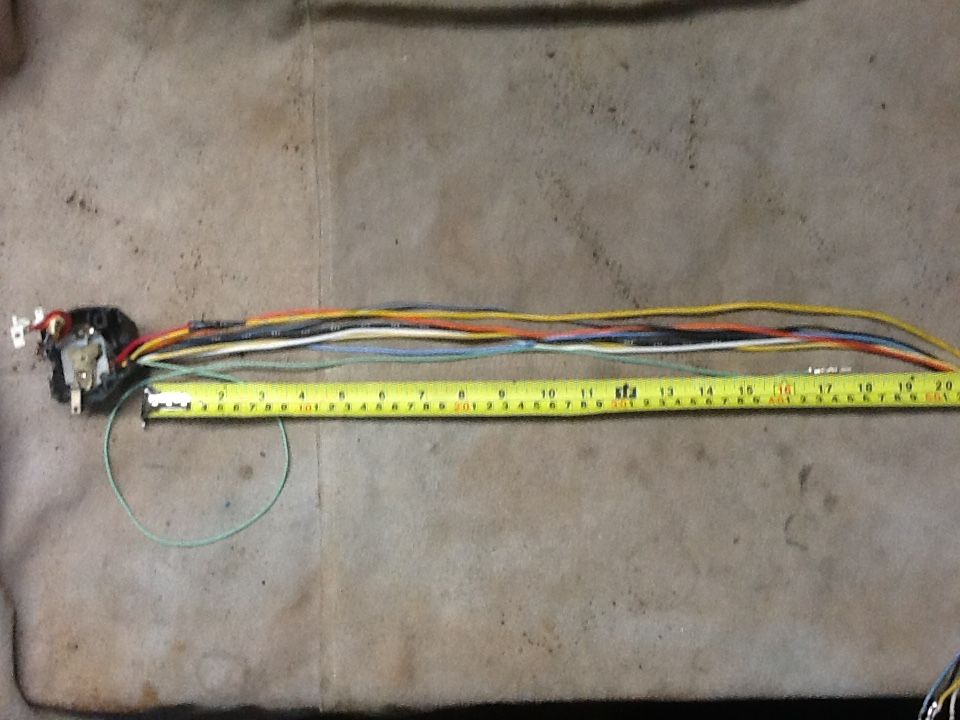

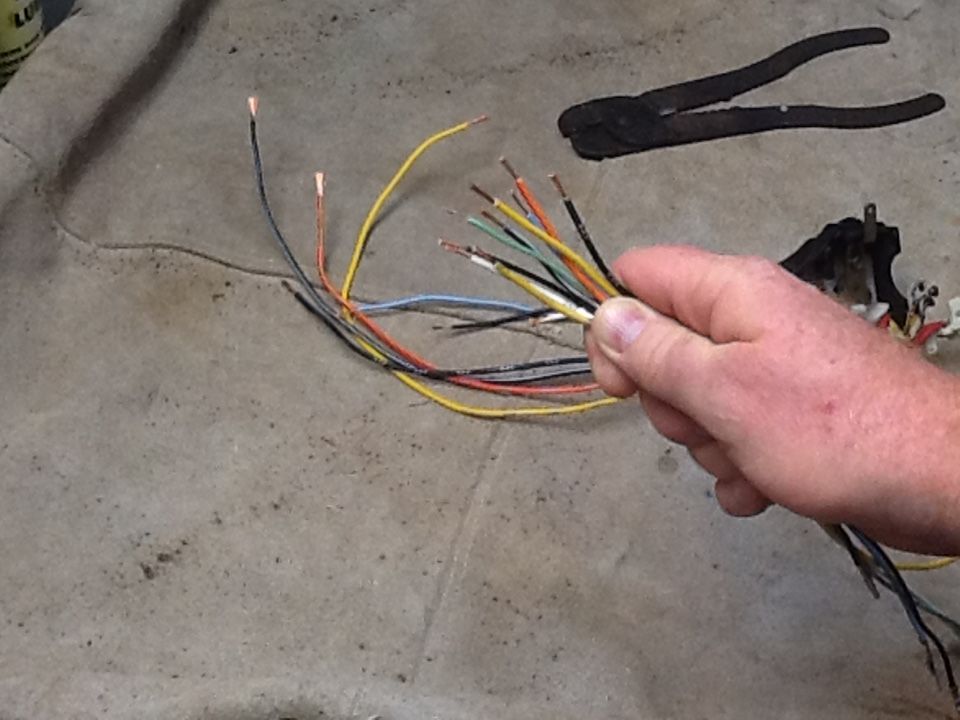

This switch block is off a GSXR750 from early 2000 vintage. It’s just one I found in the pile of crap in my garage. It’s got 9 wires . Most switchblocks from “vintage” bikes will have between 5 and 7 wires. This principle works with pretty much any switchblock anyway:

As you can see, this one has had some issues in the past, but never mind....

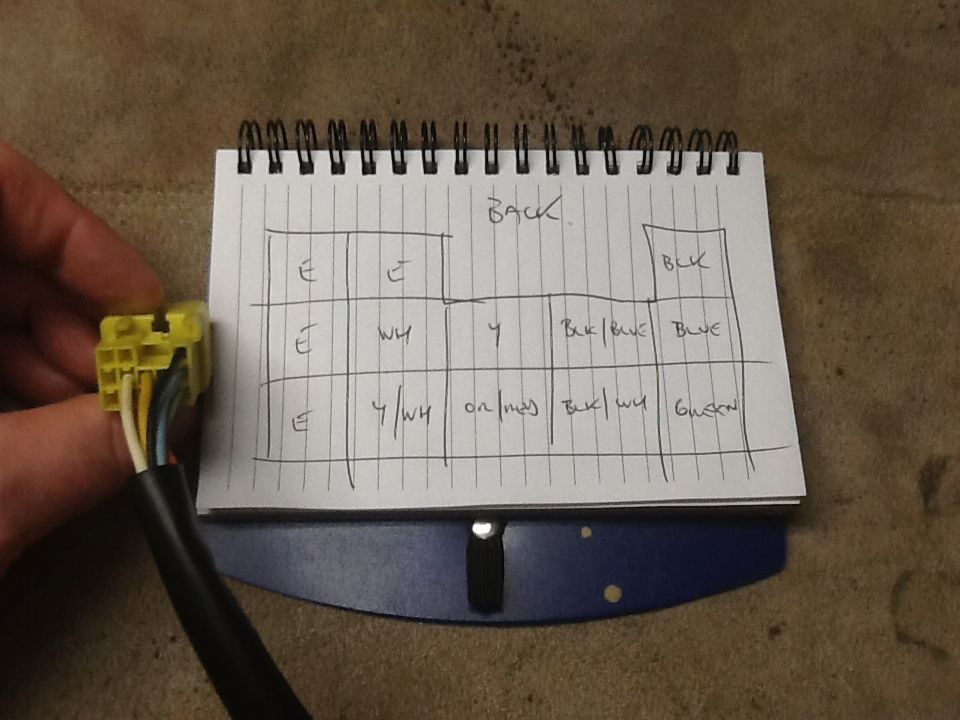

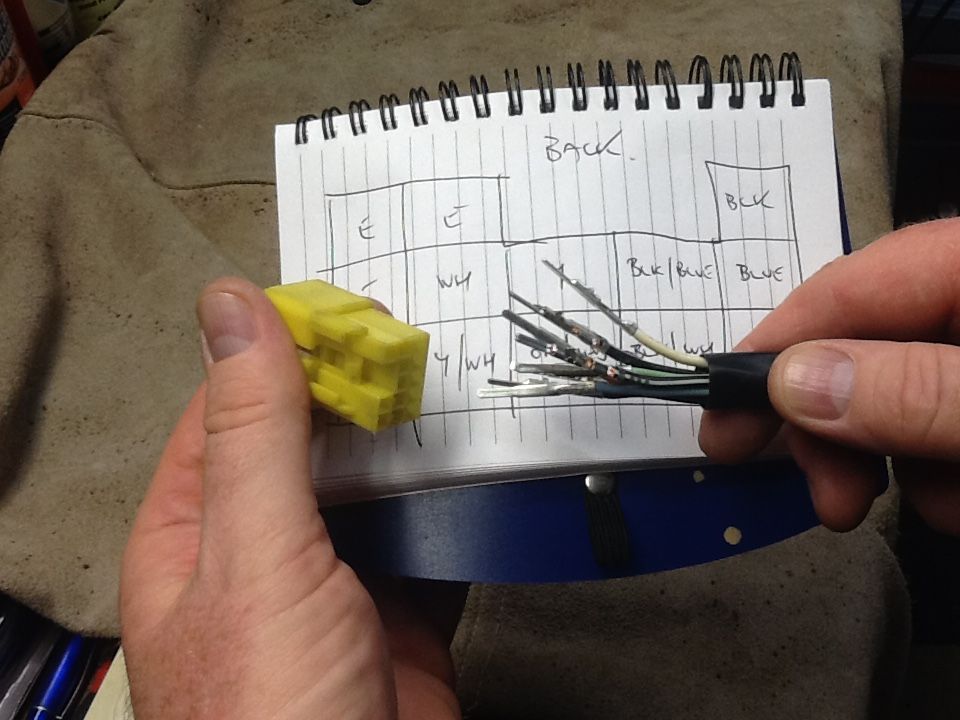

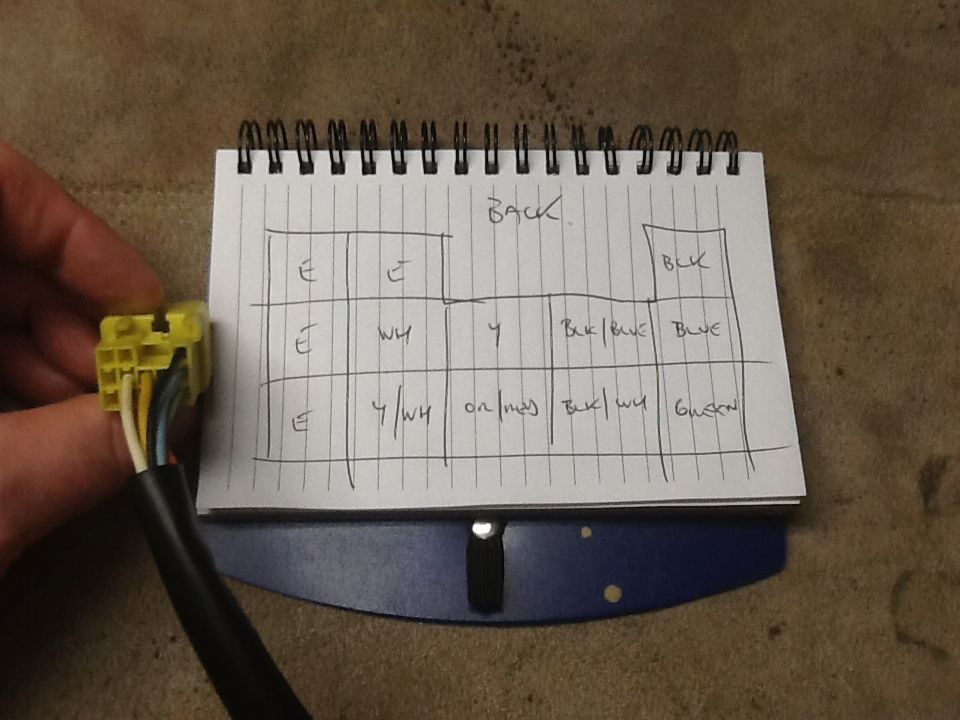

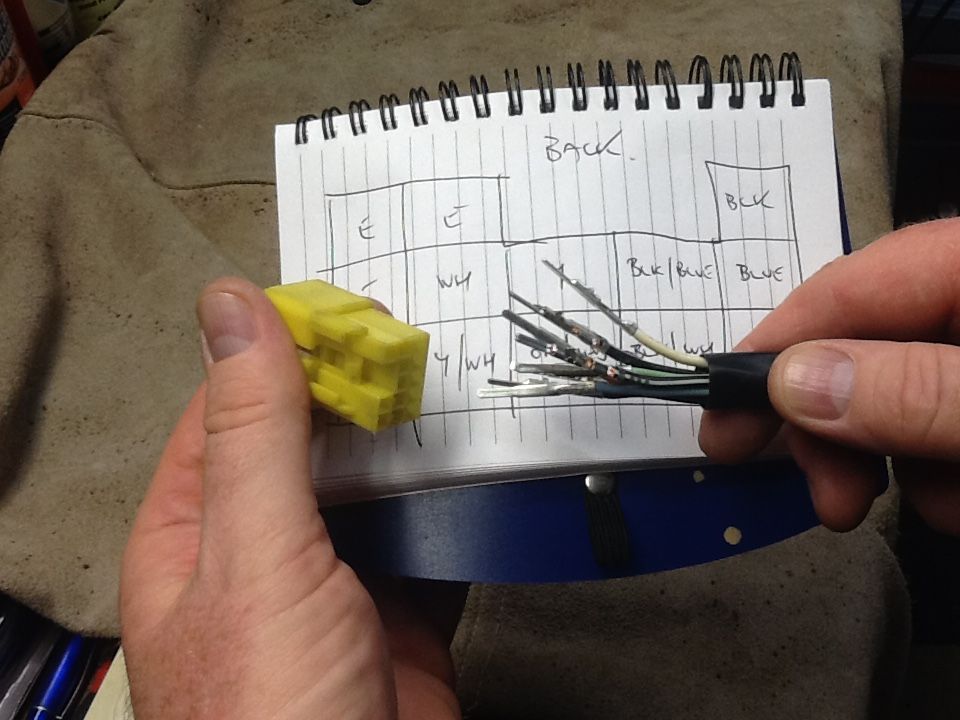

First up, draw a diagram of the connector block so you know where the wires go back in. If by chance you have 2 wires the same colour (pretty unlikely) you’ll have to mark one of them and the connector to know where it goes:

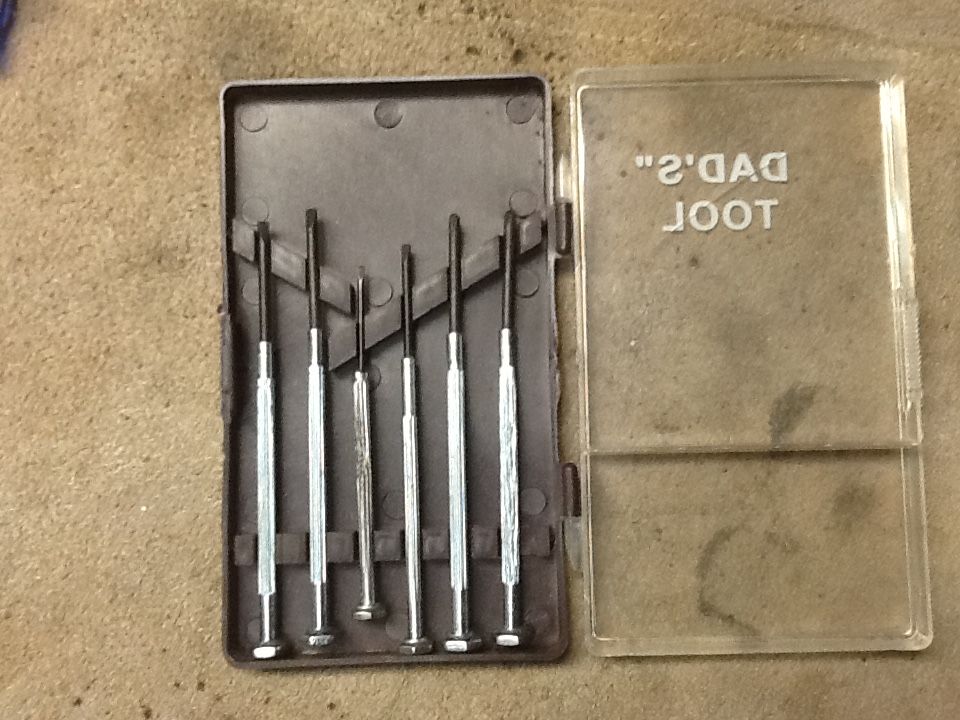

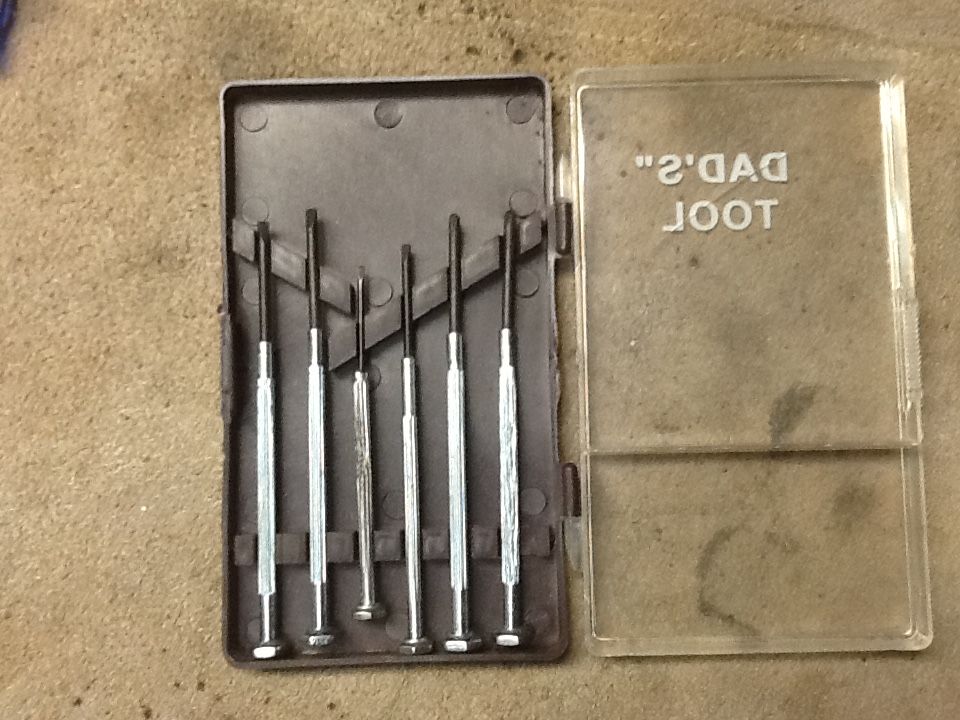

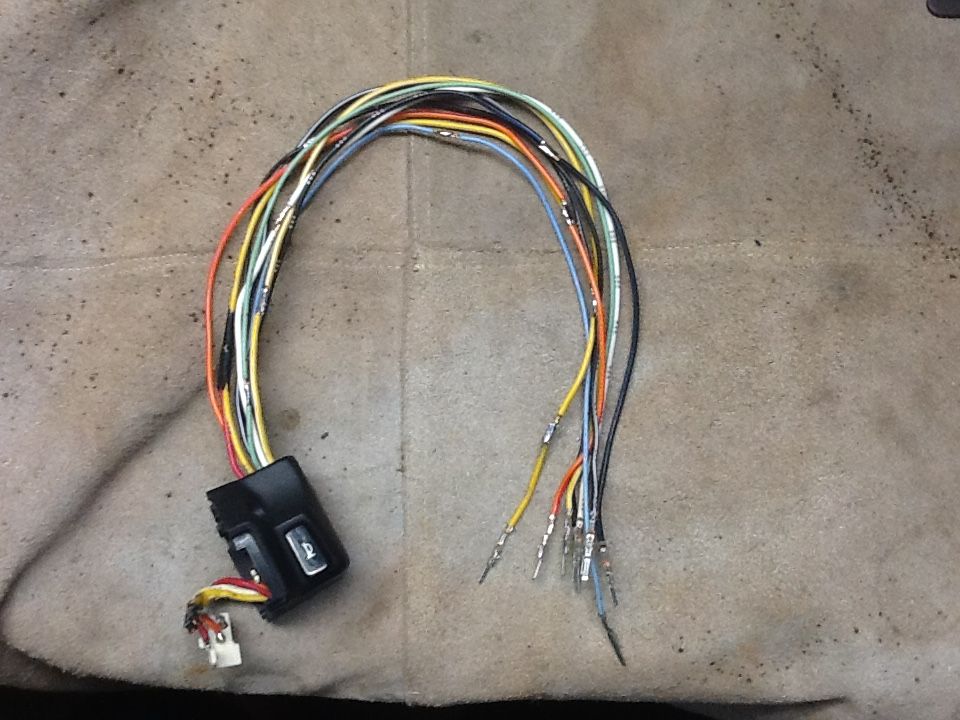

Then, using a suitable tool, push back the retaining pins and pull out the terminals (these little hobby screwdrivers work quite well)

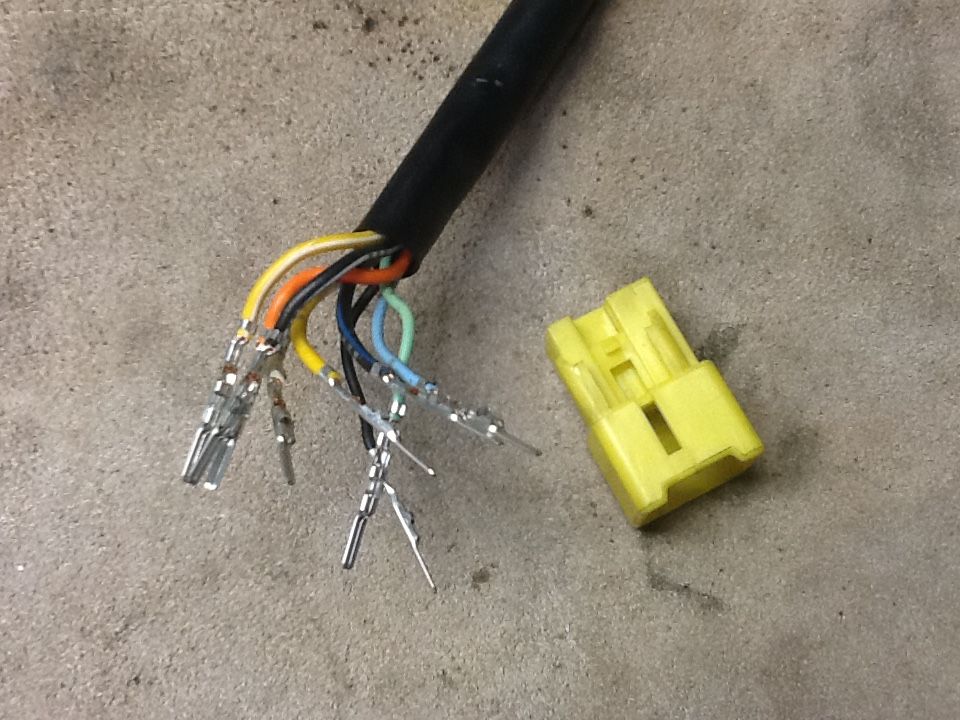

Some terminals have a locking tab built into the pins that you have to press back to extract it from the block, this one has the retaining tabs in the plastic of the block, so it's a bit easier to get the pins out.

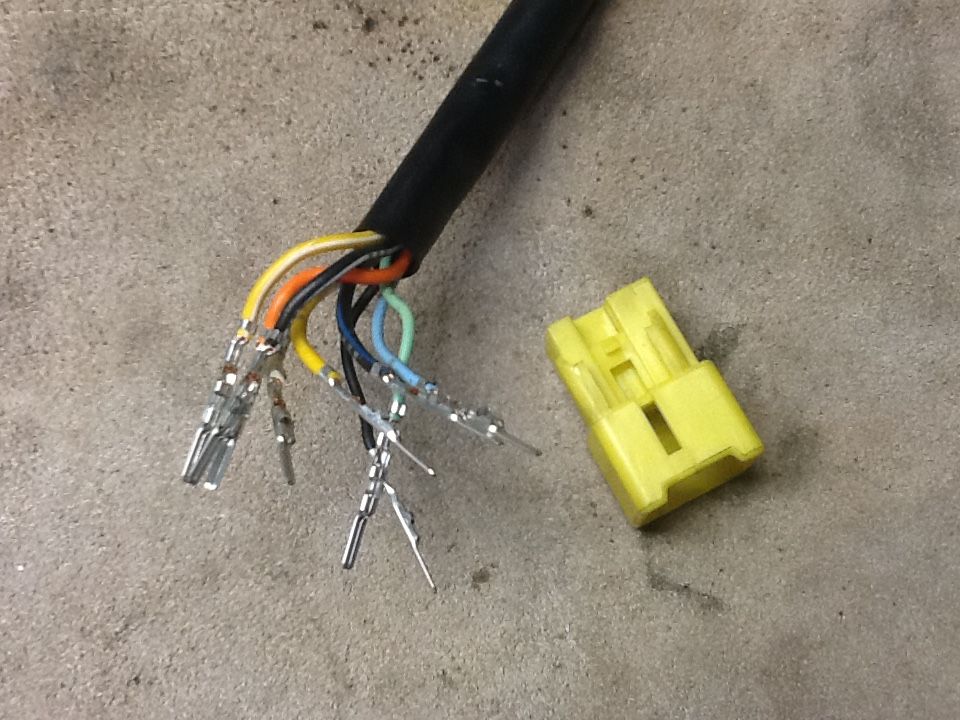

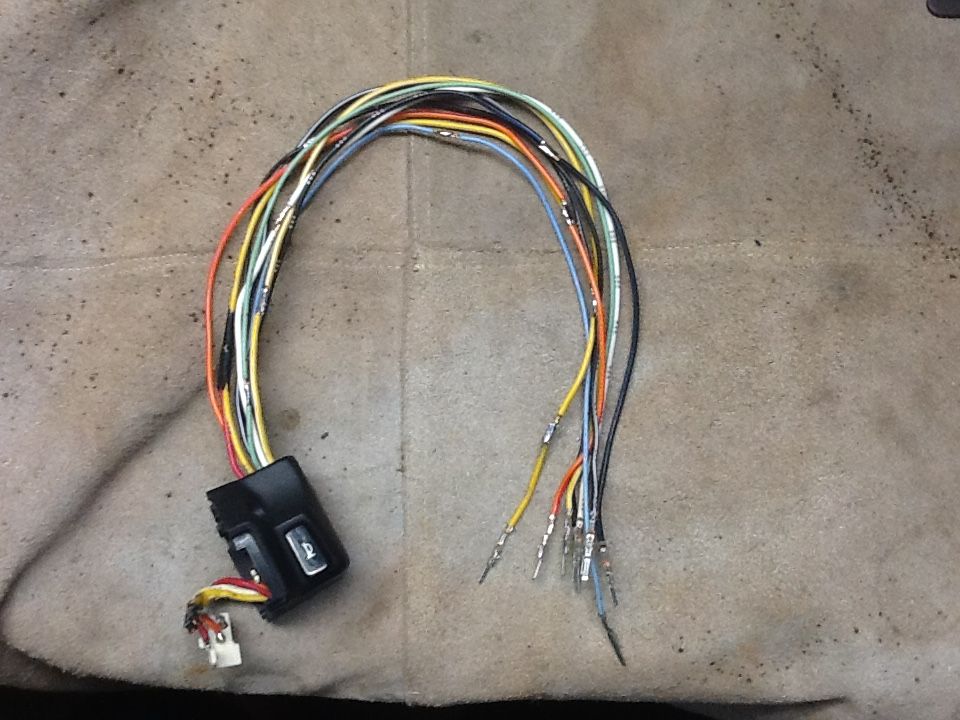

Now, slide the sheathing off the wires. If you can’t do this in one go because of the bulk of the terminals you might need to pull a few out at a time:

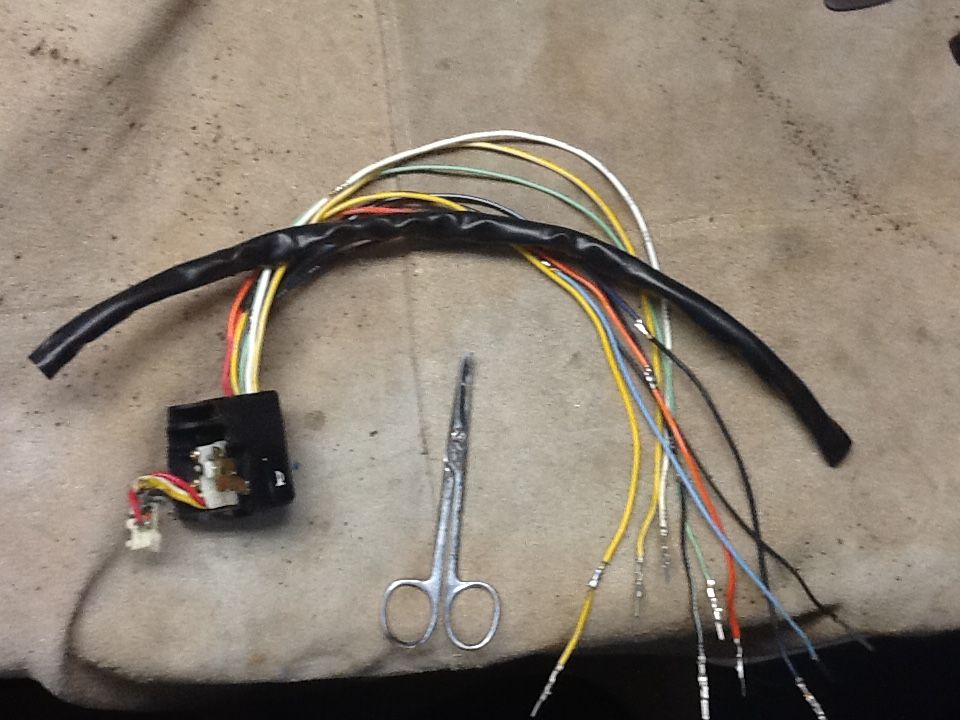

Work out how much wire you want to take out:

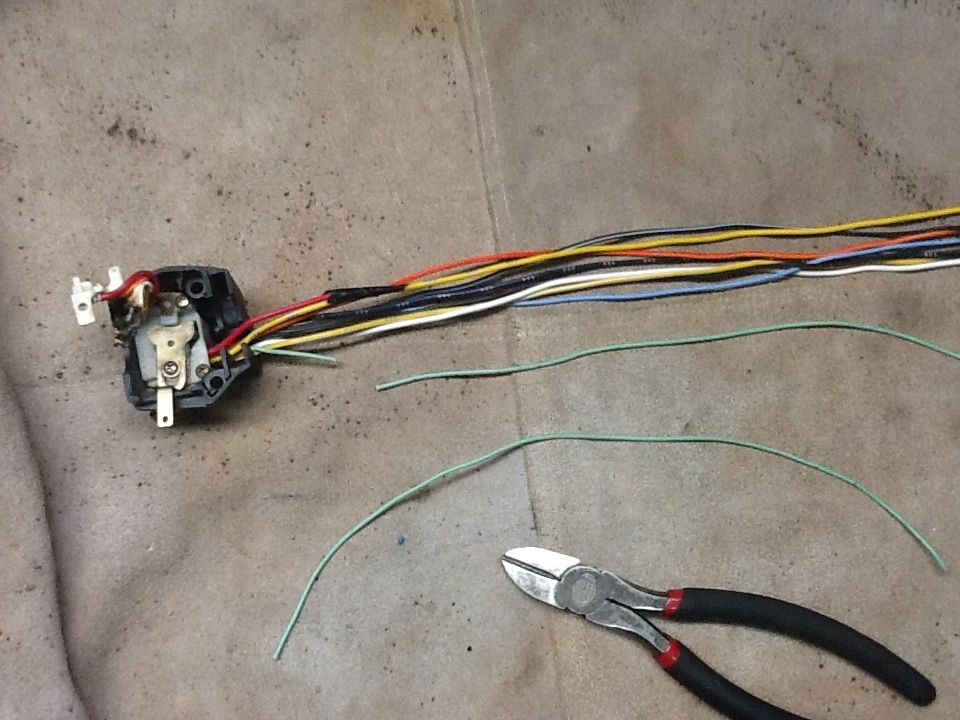

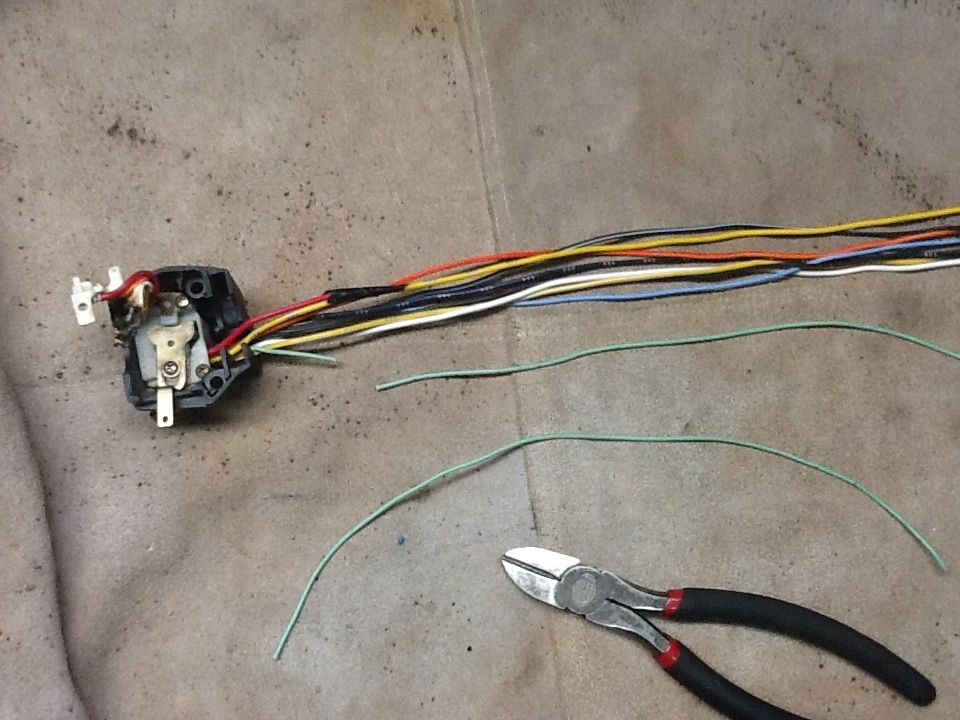

Cut the first wire up near the switchblock end and keep the bit you’ve removed:

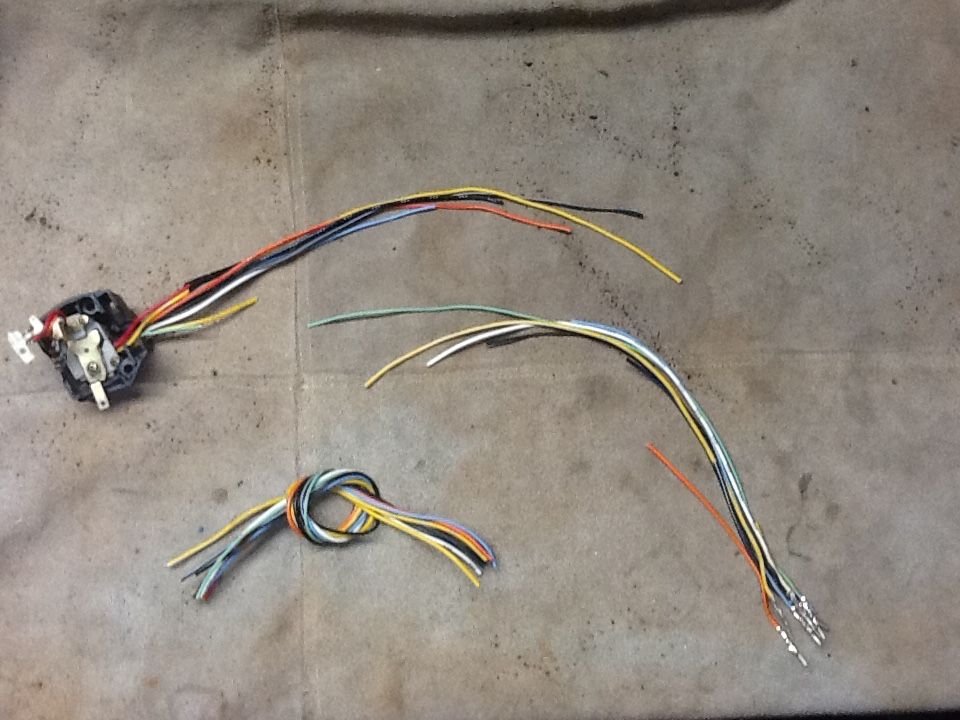

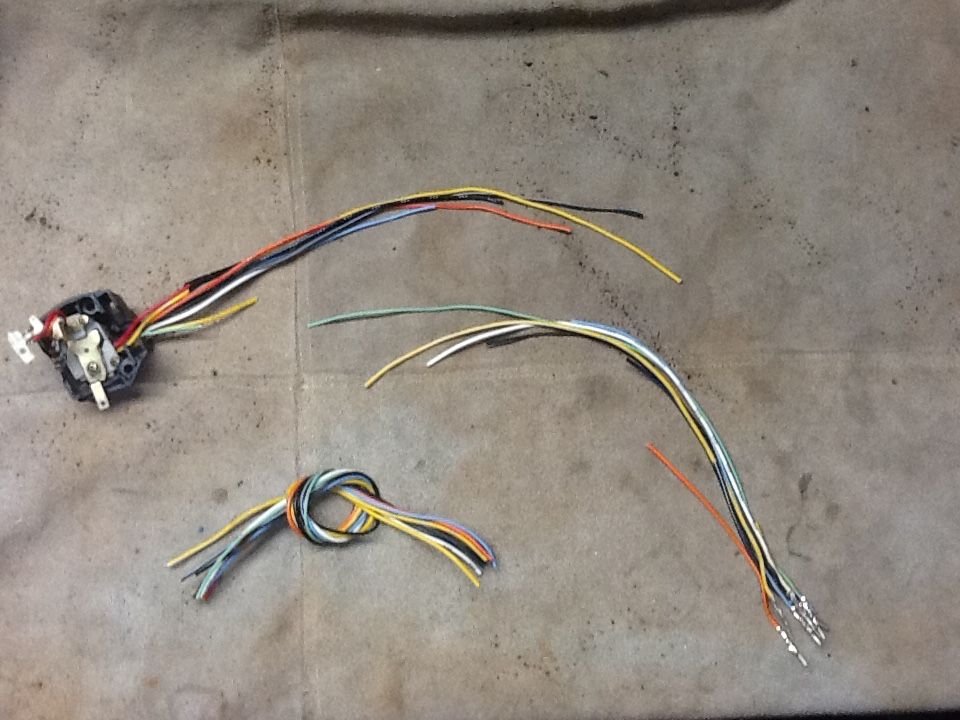

Stagger the cuts along the length of the harness. If you do this correctly / have enough room you can re-join the wires and not need to individually insulate them. If you have 2 wires the same colour it’s a good idea to do one at the start and the other at the end so you can be sure you don’t mix them up. Use the piece you removed from the first wire cut as a template for shortening the rest of the harness.

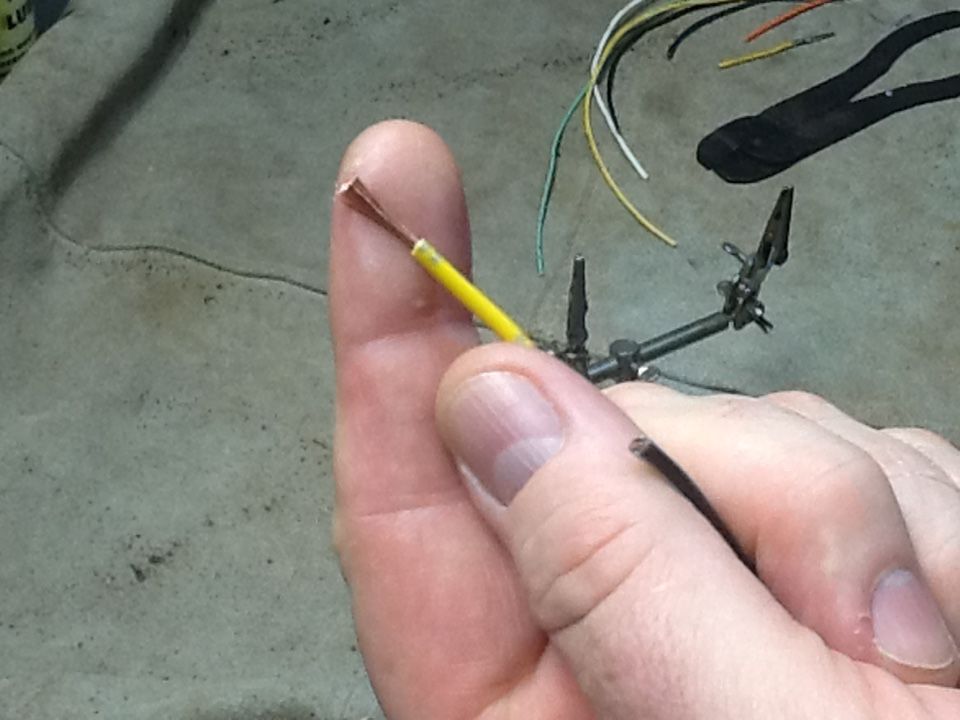

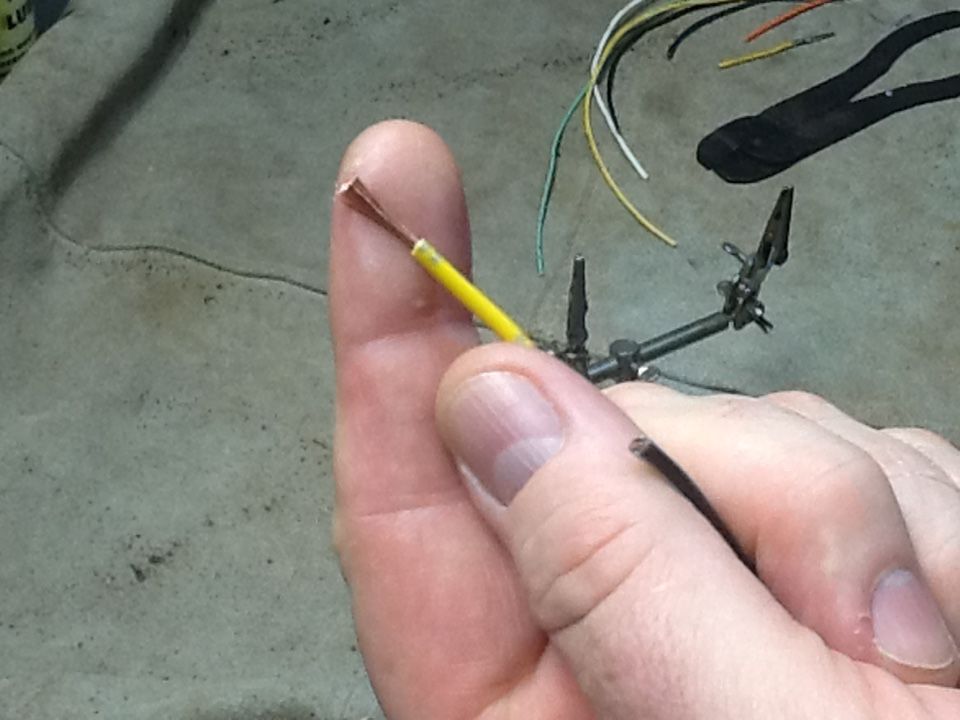

Strip about 1cm or 3/8” off each end of the wires:

If you are using individual heat shrink to insulate each wire, PUT THEM ON NOW. You will forget at some stage and you usually only remember when the soldering iron is turned off and cold.

Solder up the wires. These things are really handy...

You can do this either by individually tinning the ends and then soldering them together side by side, or just pushing the bare wires into each other and soldering them in situ. Either way works — the latter is probably neater / less intrusive if you are using heatshrink for the outside of the wiring instead of sheathing......but I prefer tinning the individual leads and then soldering them together as I feel this ensures the solder flows into the wires better:

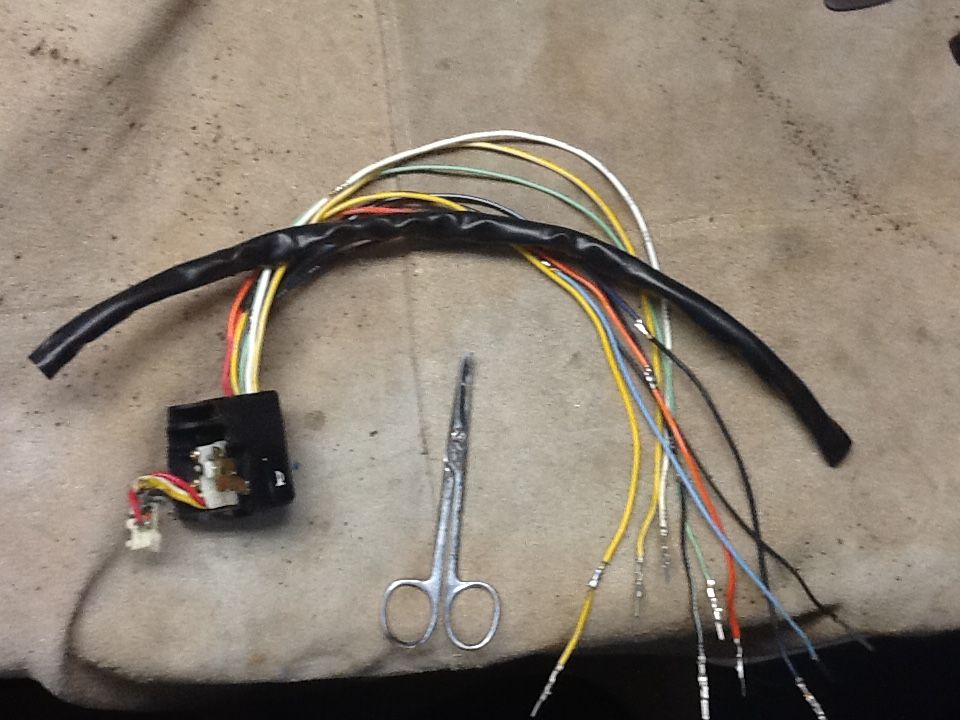

Trim the sheathing / heatshrink to the new length and slide it back on:

Put all the terminals back in as per your diagram.

Job done — drink beer

This method can be used for lengthening or shortening the wiring going to your switchblocks. For ease of posting, I’ve chosen to shorten this one. If you are lengthening yours (like for a streetfighter bar conversion), then you pretty much do the same thing except adding a piece of wire in the middle (duh) and having 2 solder joins per wire instead of one. You can either add some extra outer sheathing, buy a new length, or use heatshrink.

We are going to re-use the pins and the connector block in this exercise. You could go all full retard and buy something like fancy Deutsch connectors and think you’re improving things but if you actually look inside your switchblock and see how the switches work, well, fancy connectors in this application would be like putting racing slicks on a warehouse hand trolley. Also, changing the connectors means if you ever have to buy another switchblock (like if you slide down the road and FUBAR this one) you have eliminated the plug and play aspect and are in for another night with the soldering iron / crimpers.

This switch block is off a GSXR750 from early 2000 vintage. It’s just one I found in the pile of crap in my garage. It’s got 9 wires . Most switchblocks from “vintage” bikes will have between 5 and 7 wires. This principle works with pretty much any switchblock anyway:

As you can see, this one has had some issues in the past, but never mind....

First up, draw a diagram of the connector block so you know where the wires go back in. If by chance you have 2 wires the same colour (pretty unlikely) you’ll have to mark one of them and the connector to know where it goes:

Then, using a suitable tool, push back the retaining pins and pull out the terminals (these little hobby screwdrivers work quite well)

Some terminals have a locking tab built into the pins that you have to press back to extract it from the block, this one has the retaining tabs in the plastic of the block, so it's a bit easier to get the pins out.

Now, slide the sheathing off the wires. If you can’t do this in one go because of the bulk of the terminals you might need to pull a few out at a time:

Work out how much wire you want to take out:

Cut the first wire up near the switchblock end and keep the bit you’ve removed:

Stagger the cuts along the length of the harness. If you do this correctly / have enough room you can re-join the wires and not need to individually insulate them. If you have 2 wires the same colour it’s a good idea to do one at the start and the other at the end so you can be sure you don’t mix them up. Use the piece you removed from the first wire cut as a template for shortening the rest of the harness.

Strip about 1cm or 3/8” off each end of the wires:

If you are using individual heat shrink to insulate each wire, PUT THEM ON NOW. You will forget at some stage and you usually only remember when the soldering iron is turned off and cold.

Solder up the wires. These things are really handy...

You can do this either by individually tinning the ends and then soldering them together side by side, or just pushing the bare wires into each other and soldering them in situ. Either way works — the latter is probably neater / less intrusive if you are using heatshrink for the outside of the wiring instead of sheathing......but I prefer tinning the individual leads and then soldering them together as I feel this ensures the solder flows into the wires better:

Trim the sheathing / heatshrink to the new length and slide it back on:

Put all the terminals back in as per your diagram.

Job done — drink beer